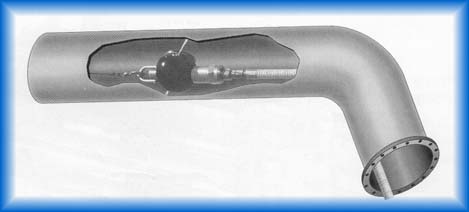

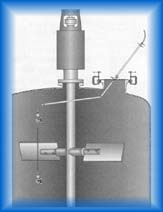

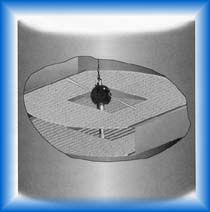

3-Dimensional Nozzle

Rotates about two axes, jets hit all surfaces from one position.

OSHA

Regulation Title 29 CFP 1910.146

Confined Space Entry Precautions

This regulation protects workers who enter confined spaces from asphyxiation, and other hazards of an environment not normally safe for people to work in. Similar regulations have been adopted by other countries. These common sense rules require that all sources of hazardous materials, powered equipment, and inert blankets be isolated from the vessel. Adequate ventilation must be provided, with backup provisions. Furthermore, rescue personnel and equipment are required in case the workers do become overcome by hazardous materials, or inadequate breathing air. Training of personnel must be completed and documented. These precautions save lives, and are really important for contractors who must do this type work.

These precautions are costly though, making it wise to avoid vessel entry whenever possible. Use of 3-D waterblast nozzles can often eliminate the need for vessel entry, allow more thorough cleaning than possible with men inside the vessel, and completion of the job more quickly. Downtime costing $ 15,000 per hour in lost sales is not unusual for a process plant, making the service more valuable for the contractor who can turn the cleaned vessel back for production in the least downtime.